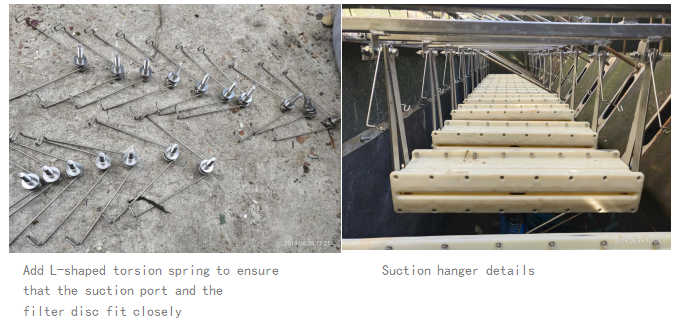

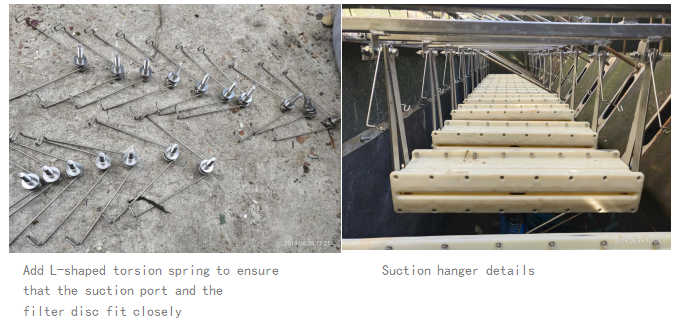

A domestic sewage treatment plant was built in 2016 with a design scale of 20,000 cubic meters per day. The advanced treatment process is a fiber turntable filter. Two Jiangsu equipments are used with a diameter of 2 meters and each equipment has 10 circles. The equipment is operating poorly, the water flux is low, the equipment is backwashed frequently, and it is in an overflow state. After on-site inspection and maintenance, the equipment had the following problems: 1. Multiple electric ball valve actuators failed and could not be opened and closed normally. 2. The design of the backwash system is unreasonable. The suction nozzles of the filter discs are fixed by springs, and the angle changes are small. The filter discs and the suction ports cannot be completely fitted, and the equipment has a poor backwash effect. 3. The equipment uses ordinary polyester filter cloth, the base cloth is dense, the fiber is crimped, and the flux and filter cloth regeneration performance are poor.

In response to the above problems, our company signed a turntable filter overhaul contract with the water plant to comprehensively repair the equipment, including replacement of electric ball valves, rectification of the backwash system, replacement of filter cloth, and commissioning of the whole machine. Original accessories, new iron filter cloth with iron anchor. The entire project is overhauled, the equipment backwash interval is longer, and the overall energy consumption is reduced, which effectively solves the problem for the owner.

Site construction pictures:

| 中文

| 中文